Established in 2015, Zhengzhou Fangming High-Temperature Ceramic New Material Co., Ltd. focuses on the research, development, production, and sales of nano-zirconia materials and products. The company's dedication to enhancing its technological capabilities and product offerings has led to the successful development of ultra-high temperature and high-purity composite ceramic products based on oxide nano materials.

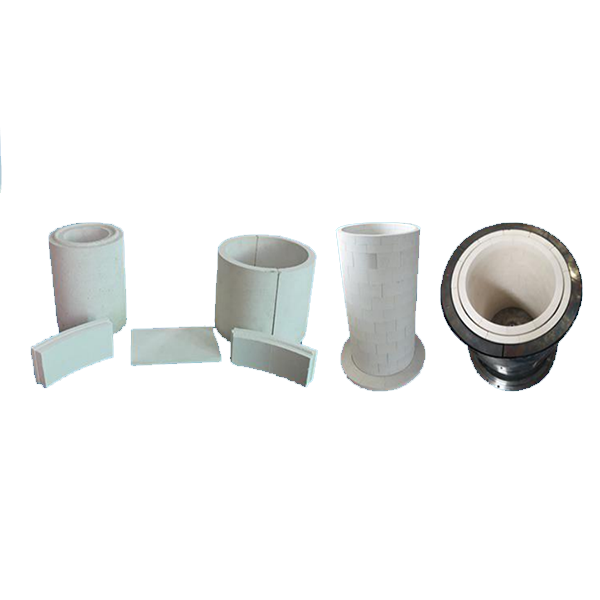

The newest addition to the company's portfolio, the Alumina Silica Refractory, is a cutting-edge material designed to withstand extreme temperatures and harsh operating conditions. With excellent thermal shock resistance and high mechanical strength, this refractory material is poised to deliver superior performance in a variety of industrial settings.

One of the key characteristics of the Alumina Silica Refractory is its exceptional resistance to thermal shock. This property allows the material to maintain its structural integrity when exposed to rapid changes in temperature, making it an ideal choice for applications where heat fluctuations are common. Whether utilized in furnaces, kilns, or other high-temperature equipment, this refractory material offers long-lasting durability and reliability.

In addition to its outstanding thermal shock resistance, the Alumina Silica Refractory also boasts high mechanical strength, making it capable of withstanding significant mechanical and thermal stresses. This attribute is particularly valuable in industries such as glass manufacturing, metal smelting, and petrochemical processing, where materials are subjected to intense heat and pressure.

The introduction of the Alumina Silica Refractory underscores Zhengzhou Fangming High-Temperature Ceramic New Material Co., Ltd.'s commitment to providing innovative solutions that meet the evolving needs of the industry. By leveraging its expertise in nano materials and advanced manufacturing techniques, the company is positioned to deliver high-performance refractory products that drive efficiency and productivity for its customers.

"We are thrilled to bring our Alumina Silica Refractory to the market, as it represents a significant advancement in our product offerings," said a spokesperson for Zhengzhou Fangming High-Temperature Ceramic New Material Co., Ltd. "This new material not only showcases our technical capabilities but also demonstrates our dedication to providing our customers with reliable, high-quality solutions."

As the global demand for high-performance refractory materials continues to rise, the launch of the Alumina Silica Refractory positions Zhengzhou Fangming High-Temperature Ceramic New Material Co., Ltd. as a key player in the industry. With its commitment to research and development, the company is well-equipped to address the complex challenges faced by various sectors, including steel production, cement manufacturing, and power generation.

The Alumina Silica Refractory is poised to make a significant impact in the industrial landscape, offering a viable solution for companies seeking to optimize their operations and enhance the performance of their equipment. As industries increasingly rely on advanced materials to meet stringent performance requirements, the revolutionary properties of this refractory material are expected to drive substantial interest and adoption across diverse market segments.

With the successful introduction of the Alumina Silica Refractory, Zhengzhou Fangming High-Temperature Ceramic New Material Co., Ltd. has reaffirmed its position as a leading provider of innovative ceramic materials. As the company continues to push the boundaries of technological innovation, its steadfast commitment to excellence sets the stage for continued success and industry leadership in the years to come.